I can faintly hear the clip and clop of my pridefully-chosen designer leather boots on the polished concrete as I make my way through the organized chaos. The rhythmic cacophony of man, machine and robot working together like a technological ballet brought together by the amalgamated minds of Nikola Tesla and Pyotr Tchaikovsky is enough to leave me in wonder. Bins, aisles, canyons of steel shelving all carefully placed and planned and laid out. It never ceases and flows like a living organism. And I am proud, standing at the STIHL USA headquarters.

I don’t even belong here. I was invited, surely, but this is just a fleeting moment…a glimpse into the birthplace of some of my fondest memories as a child.

The STIHL factory.

STIHL USA in Virginia Beach

Despite not having any direct ties, I feel a personal sense of pride as I make my way through the busy assembly and inspection stations. It’s as though twenty years ago, my family joined an exclusive and historic club and now I am afforded the opportunity to search its catacombs, if only for a few hours. Likewise monks, the engineers and department heads whisper stories and secrets as I peruse the many treasures being assembled.

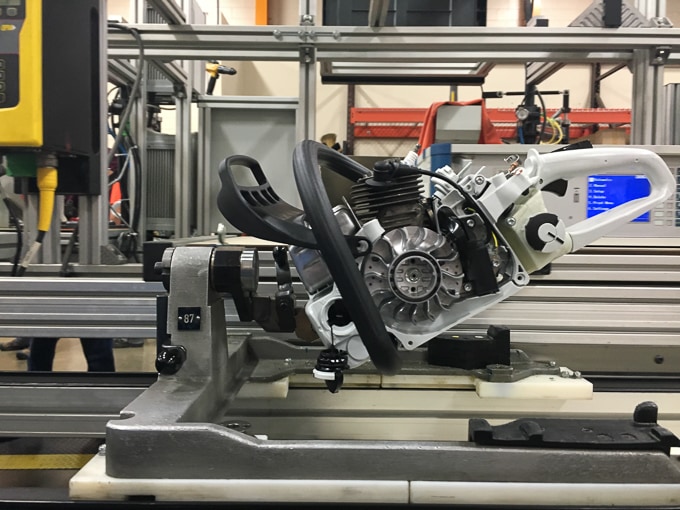

As a boy, my father taught me that quality lasts. I learned that quality takes a combination of time, diligence, precision and – in many cases – wisdom. Now, as I stand in the forging place of STIHL USA's beating hearts, I listen to the lessons learned by Piston Lead, John Wicker. A former machinist for NASA, Wicker explains how he discovered the difference between perfection and precision. He describes a time when he was new to machining at STIHL USA and believed he could improve the smoothness of the sides of the pistons. STIHL's machines were capable of variances within microns of precise cutting, but Wicker noticed that each piston – though smooth to the touch – was still microscopically grooved by what he believed to be the cutting blade as it had made its passes.

Wicker, used to making absolutely unblemished aerodynamic models for wind tunnels, wanted to “fix” the problem. However, he was assured by the engineers from STIHL's founding location in Germany that this was a terrible idea. It turns out that the “rough” edges were actually intentionally-engineered grooves so small that they felt like an imperfection. Wicker soon learned that the grooves were actually designed to hold in lubricating oil as the piston worked speedily back and forth. Without these grooves, the engines would seize and become useless.

Wisdom, knowledge through time and experience, gained.

As I walk, my mind reflects for a moment back onto my boots. I remember falling in love with them for their late 19th century style from which they were born. It's so pragmatic and prosaic, they seem to be timelessly in fashion. Brought from the past to be seamlessly integrated into today's wardrobe.

As it turns out, STIHL is doing the same thing.

STIHL is Balancing Past and Future

In 1926, Andreas Stihl built his first chainsaw for bucking in the lumber yards. It took two men to wield and weighed just over one hundred pounds. But it didn’t run on gasoline or any other type of liquid fuel. It was electric.

Now, after mastering the gasoline engine for decades, STIHL looks to the future by returning to this old energy.

I am given a formal introduction to the new STIHL Lightning Battery System by STIHL's very own Battery Production Manager. A bundle of energy himself, Brian Manke is a handsome man enamored by historical greats such as Tesla.

He is the perfect person for the job.

Gas vs Battery, STIHL USA Meets the Need

Manke tells me STIHL USA is coming out with two new lines of battery-powered tools called the AK and AI series. Unlike the existing professional series of battery-powered tools made for field use and designated heavy duty shops, the new AK and AI models are made for people who do not need constant – and sometimes overwhelming – utility. The goal of STIHL is to provide new and small home owners with the ability to harness the historical power and possibilities of STIHL without the entourage of supply that a traditional tool might take.

Now, it's STIHL on-demand.

Just before Chelsea and I bought our first home, we lived in the quaint suburb of San Marcos here in southern California. It was everything you'd expect from a stereotypical cul-de-sac, including the neighborly wave as you drive down the street. We had a small attached garage with little room. There wasn’t much work to be done, so a full size chainsaw and trimmer tools would have been overkill. What’s more, working with fuel cans would have made an odor-sensitive, pregnant Chelsea rather upset.

Don't get me wrong – I love those fuel cans for my current, more heavy-duty tasks on the farm – but I recognize that most people don't necessarily spend their days clearing orange groves and feeding a wood stove like we do. That's overkill for a more modern, clean-cut, 9-to-5 kind of family that simply needs to get a hedge under control. We've experienced the whole “good fences makes good neighbors” kind of life, and I'll admit that quiet chainsaws probably help further a neighborly atmosphere as well.

This is the perfect scenario for the AK and AI Lighting Battery Series from STIHL. The line doesn't cut any corners, still using their own quality chains, guide bars and safety features like the chain brake, just in an electric version.

You can leave this series plugged in on its stand and when you need it, at the pull of a trigger, get work done. Enough work on one battery, in fact, that you could pretty much cut every hedge at your house and move on to your neighbor's house, your neighbor’s neighbor and down the block to the stop sign before needing to swap out batteries or recharge.

How very neighborly!

Just like my dad taught me, quality lasts. The test of time makes marks on us, like those invisibly-intentional grooves on the side of a piston. One of the marks of quality, is the ability to grow and open up your mind to possibilities that may seem foreign at first, like Wicker's conceptualization of STIHL's pistons versus the wind tunnel models he was used to working with.

What fits one situation may not necessarily fit another. We glean knowledge from experience and we adjust according to our environment, making simple but gracefully-orchestrated decisions like using an electric tool in a cul-de-sac and busting out the gas-powered guns for the farm.

There's value in that pragmatism. A lesson that will stand the test of time.

Seamless integration.